CASE STUDY - Onvector

LOVE THAT DIRTY WATER

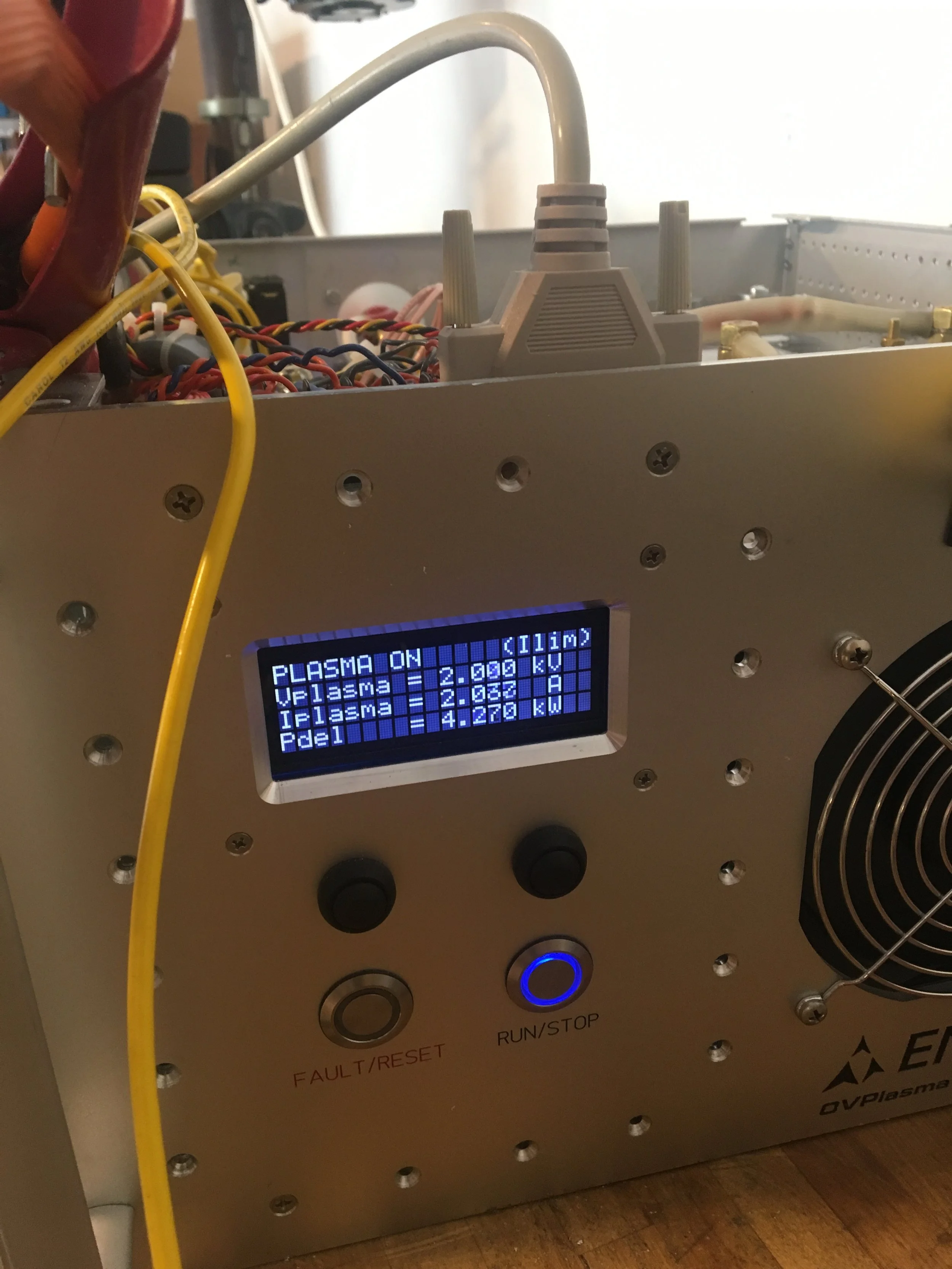

In 2015 a university-based startup client approached me with a novel technological approach to water treatment using direct water-plasma interactions. Since this technology was born on the whiteboard and had not even been demonstrated in the lab yet, my clients needed a lot of help developing both the theoretical framework for operation as well as the high voltage, high current electrical approach. Since the direct water-plasma interaction technology is entirely novel, significant new physics and chemistry principles needed development. Nielltronix was pivotal in the early days of the conceptual development and explanation of physics principles that ultimately led to successful lab demonstration and requirements flow down. In conjunction with the team’s PhDs in mechanical engineering, chemical engineering, and physical chemistry, we developed a cutting-edge model of the ion motion, ionization production, electron-liquid interactions, anodic erosion, etc. This model informed our decisions, leading ultimately to a custom high frequency AC, high voltage power supply capable of both igniting arcs in water and sustaining the ignited arc with 10-20A of sustained current. An off-the-shelf solution for this complex set of requirements simply does not exist.

Starting from these unique electrical requirements, Nielltronix began a several-year iterative design development, beginning with lab-based units and waste water testing. After several iterations in power level, high voltage design, and closed-loop control schemes, the wastewater treatment system achieved a TRL sufficiently advanced to field the technology on cruise ship, including testing abroad. The technology has been demonstrated at several military installations and has recently been shown to successfully destroy PFAS in several pilot programs. Ultimately the overall system has grown in power, complexity, and capability. The present version now allows 30kW of plasma treatment power, and automatically matches the plasma and water impedance while maintaining 1% ripple in the output current while achieving a 0.9 PF and more than 93% efficiency.